Control Cable Screened Grey | Belden 5500FE ( 0.5mm2 )

Belden 5400FE Control Cable, 2 Cores, 0.52 mm², Screen, Grey PVC Sheath, 20 AWG LIYCY SCREENED AND UN SCREED Grey color 2core 3core 4core 5core 7core 9core 12core 17core 0.5mm 0.75mm 1mm 1.5mm 2.5mm

- 24x7 Support +968 99 26 36 46

- Premium Quality

- 10 days Return & Exchange

- Deliver in 5-7 Days

- Worldwide Shipping

- Sellers can Quote

ر.ع.0.600 – ر.ع.5.400Price range: ر.ع.0.600 through ر.ع.5.400

Understanding the Control Cable Screened Grey

A Control Cable, particularly one designated as “screened grey,” is an essential component in modern industrial and automation systems. Its primary function is to reliably transmit electrical signals for control, measurement, and regulation purposes. The term “screened” is crucial here, indicating the presence of an internal conductive layer—typically a braided shield of tinned copper wires or an aluminum foil wrapped around the insulated cores. This screen acts as a vital barrier, protecting the sensitive signals within from external electromagnetic interference (EMI). Such interference can originate from a variety of sources, including powerful motors, electrical switchgear, adjacent power cables, or even radio frequencies, all of which could otherwise corrupt data transmission. The screening also works in reverse, preventing the cable from emitting its own electromagnetic noise that could disrupt nearby electronic devices.

The grey outer sheath is a common characteristic, usually manufactured from PVC (Polyvinyl Chloride). PVC is a popular choice due to its excellent balance of flexibility, making the cable easy to route and install, and its durability, offering resistance to abrasion, oils, and various chemicals like acids and caustic solutions. For more demanding environments, some variants may feature a more robust PUR (Polyurethane) sheath, which provides superior mechanical strength, tear resistance, and often better chemical and UV protection for outdoor or harsher industrial applications.

Internally, these cables contain multiple cores, each individually insulated (often with PVC) and clearly color-coded or numbered. This systematic identification simplifies wiring, installation, and troubleshooting. The flexibility of these cables makes them suitable for both static installations and dynamic applications where they might experience occasional movement, vibration, or bending, such as on automated production lines, conveyor belts, or within intricate machinery. Their robust construction and effective screening ensure signal integrity, making them indispensable in machine tool industries, process control systems, robotics, and other industrial automation settings where reliable and interference-free communication is paramount. They are generally recommended for use in dry, damp, or wet indoor environments.

Related

| Size | 12C x 0.5mm2, 19C x 0.5mm2, 2C x 0.5mm2, 3C x 0.5mm2, 4C x 0.5mm2, 5C x 0.5mm2, 7C x 0.5mm2, 9C x 0.5mm2 |

|---|

Related products

Portable Electric Space Heater –1500 / 750W

ر.ع.38.000Original price was: ر.ع.38.000.ر.ع.37.300Current price is: ر.ع.37.300.

ABB T7 MCCB 4P 1250AMP 70kA

High Power Adjustable Resistor | 50W-10KW 5Ω–1kΩ

German Schuko Socket | 2Gang 2P+E IP54

ر.ع.13.800Original price was: ر.ع.13.800.ر.ع.12.400Current price is: ر.ع.12.400.

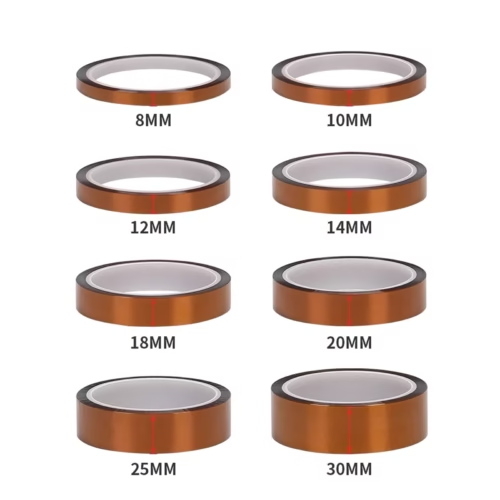

High Temperature | Polyimide Tape

ر.ع.5.800Original price was: ر.ع.5.800.ر.ع.5.300Current price is: ر.ع.5.300.

Flat Copper Braided | Connecting Wire

ر.ع.2.800Original price was: ر.ع.2.800.ر.ع.2.400Current price is: ر.ع.2.400.

Fluke 115 True RMS Digital Multimeter – AC/DC Volt

Hydrogen Sulfide H2S Gas Detector | High Alarm

safe Explosion Proof Mobile

Rotary Changeover Switch SZW | 660V 40A 3-Position 3-Pole,

ر.ع.28.500Original price was: ر.ع.28.500.ر.ع.27.400Current price is: ر.ع.27.400.

Weather Proof Outdoor Socket | Enclosure IP65

ر.ع.10.800Original price was: ر.ع.10.800.ر.ع.9.200Current price is: ر.ع.9.200.

Automatic Transfer Switch 440VAC | ATS

ر.ع.115.000Original price was: ر.ع.115.000.ر.ع.112.000Current price is: ر.ع.112.000.

Fluke 9040 Phase Rotation Indicator LCD

ATS Switch Automatic Transfer Switch 110V/220V

Voltage Protection Relay | Over / Under Voltage Protector

Phoenix Contact VAL-MS 230 | Surge 275V AC 40kA

Multifunctional Portable Waterproof DB

ر.ع.40.000Original price was: ر.ع.40.000.ر.ع.38.800Current price is: ر.ع.38.800.

Siemens 3RT2025-1BB40 Contactor 24VDC – 7.5kW, 400V