Twin Insulated Bootlace Lugs 0.5MM To 120MM

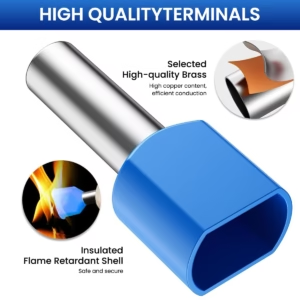

Copper material: Using excellent copper material, strong conductivity, long life, users can rest assured. Tinned surface: Copper parts are tin-plated, with strong corrosion resistance, good electrical conductivity, and reliable connection.

- 24x7 Support +968 99 26 36 46

- Premium Quality

- 10 days Return & Exchange

- Deliver in 5-7 Days

- Worldwide Shipping

- Sellers can Quote

Twin Insulated Bootlace Lugs 0.5 MM To 70 MM

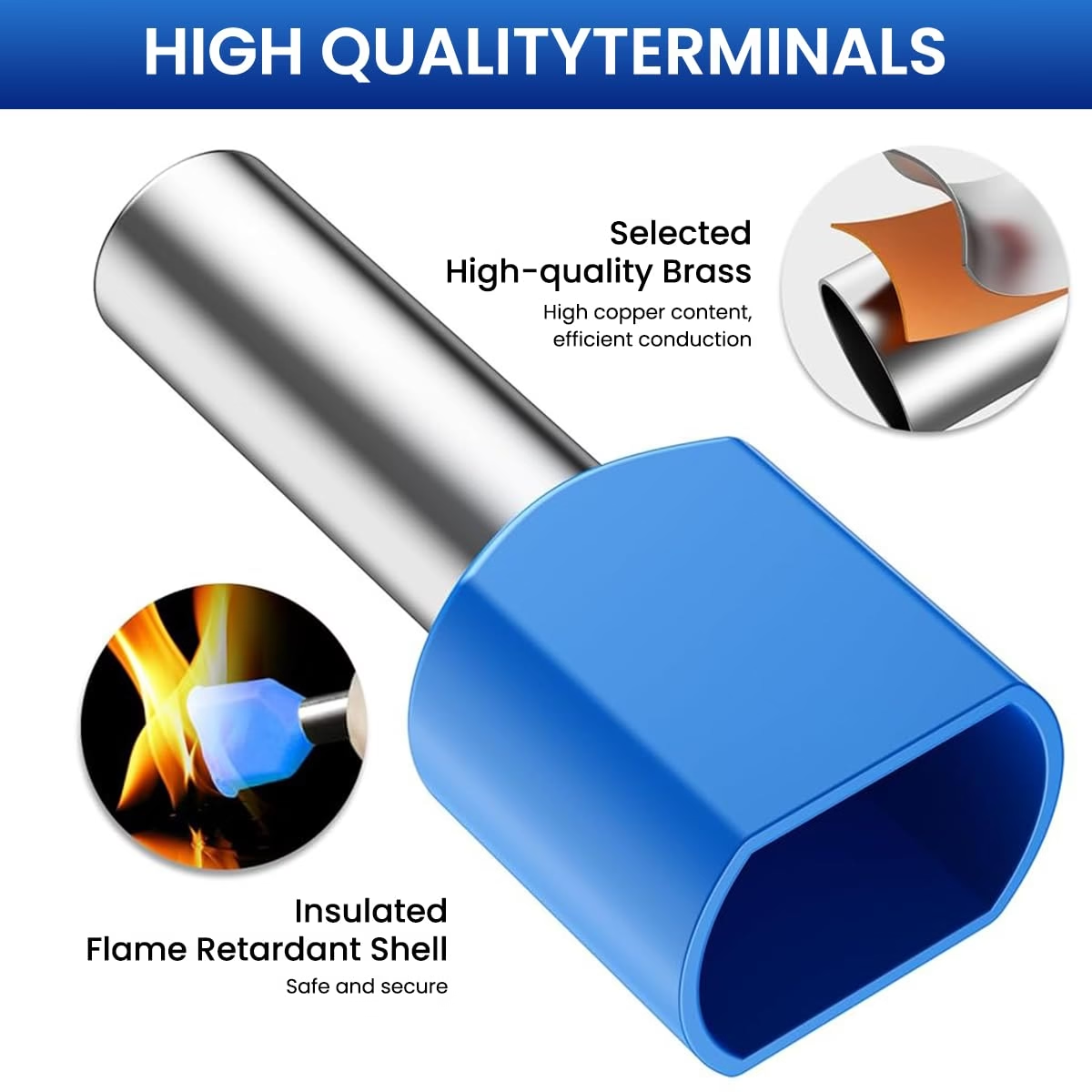

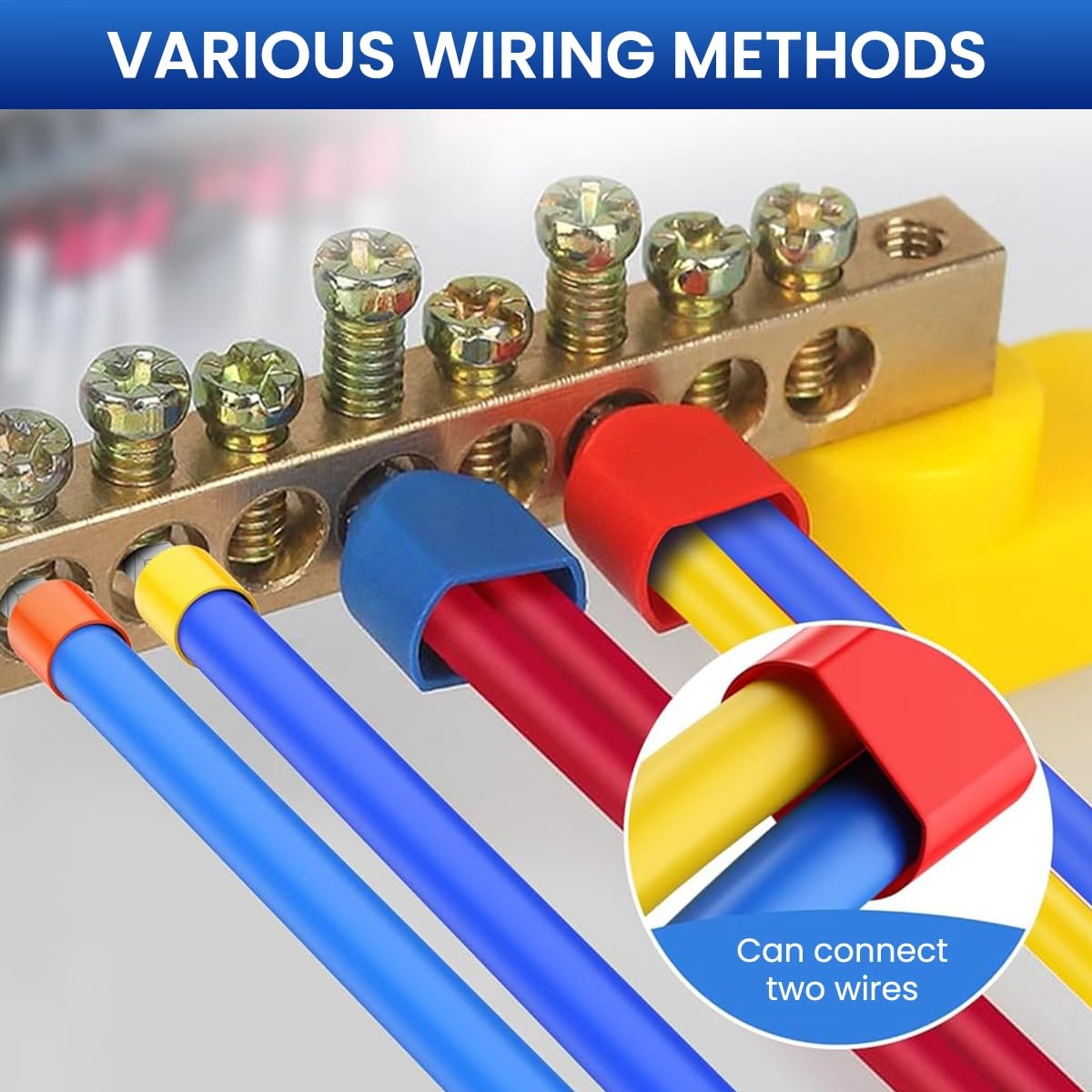

These Crimp lugs are designed to easily and securely connect and disconnect electrical joints permanently or for maintenance. These lugs are also known as Compression Type Lugs, the process is done by compressing the lug along with the cable to make a connection (crimping) using appropriate crimping tools and dies.

They are essential for using electrical connections across applications as they allow different electrical systems to connect. These lugs are made of copper for higher conductivity and also to avoid galvanic action, in which two dissimilar metals are in contact with each other causing corrosion of one metal on the other.

| Technical Details | Specifications:

|

|---|

- This insulated twin bootlace ferrule has up to 105°C heat resistance.

- It is made from polypropylene plastic and copper (EN13600), which has a tin-plated surface to protect against corrosion.

- Halogen-free.

- The colour coding of these cable end sleeves follows DIN 46228 part 4.

- Thermal insulated: The insulated twin cord end terminals are designed with thermal insulation, which can protect your cable from heat and cold.

WHY ARE THEY USED?

When the end of a multi strand wire is placed under a screw terminal the strands of the wire will fan out as the screw is tightened. In extreme cases of over-tightening the screw can even sever some of the strands of the wire. This can reduce the quality of the electrical connection and could lead to shorts. Using a bootlace crimp with all the strands captured in the ferrule tube makes for a reliable connection, that is also easier to remove and reinstall without damage to the wire ends.

SPECIFICATIONS:

- Series: TE4012

- Purity: >99.9%

- Insulation: Nylon 66

- RoHS: Yes

- Bootlace Ferrules or Cord End Terminals

- Temp Range: -40˚C to +105˚C

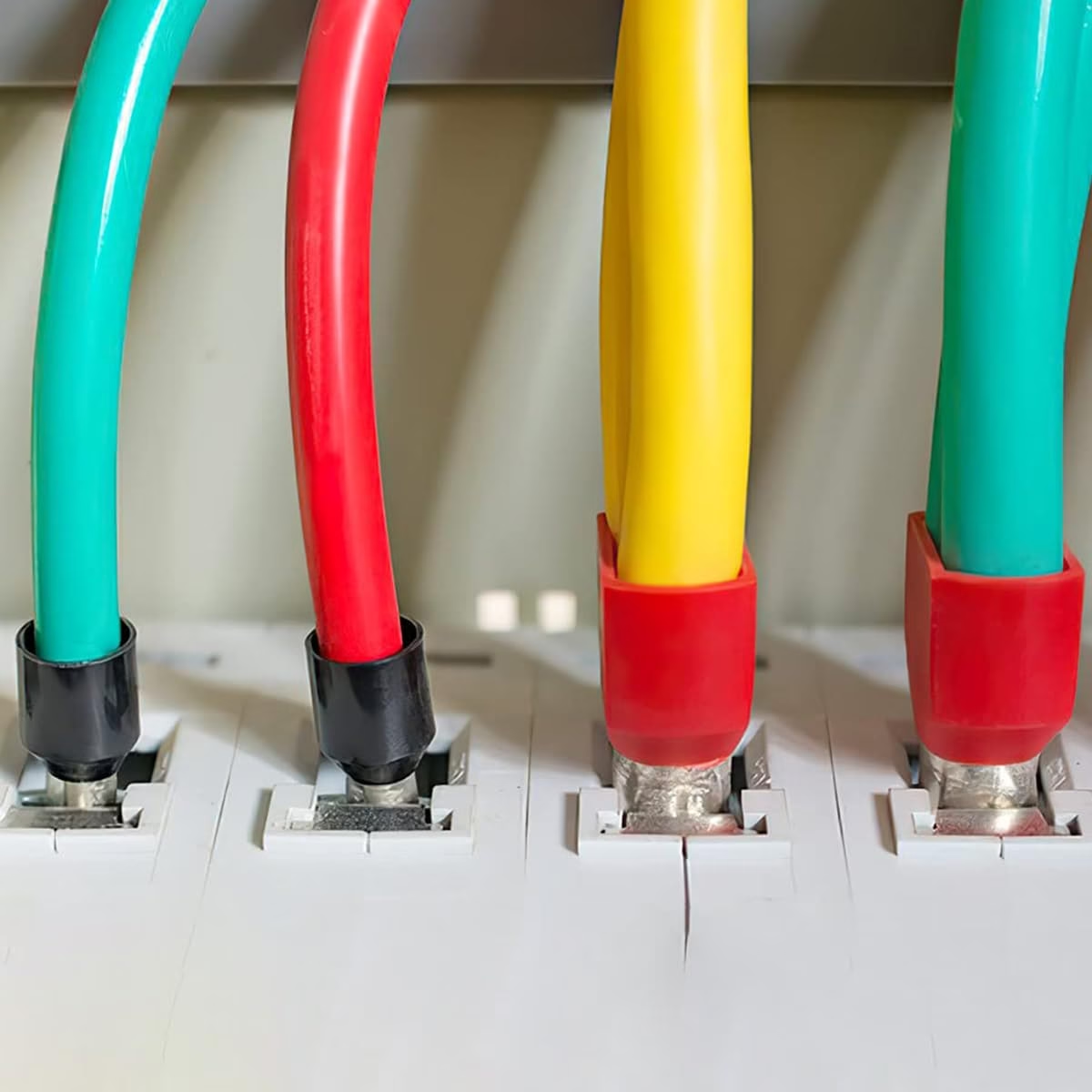

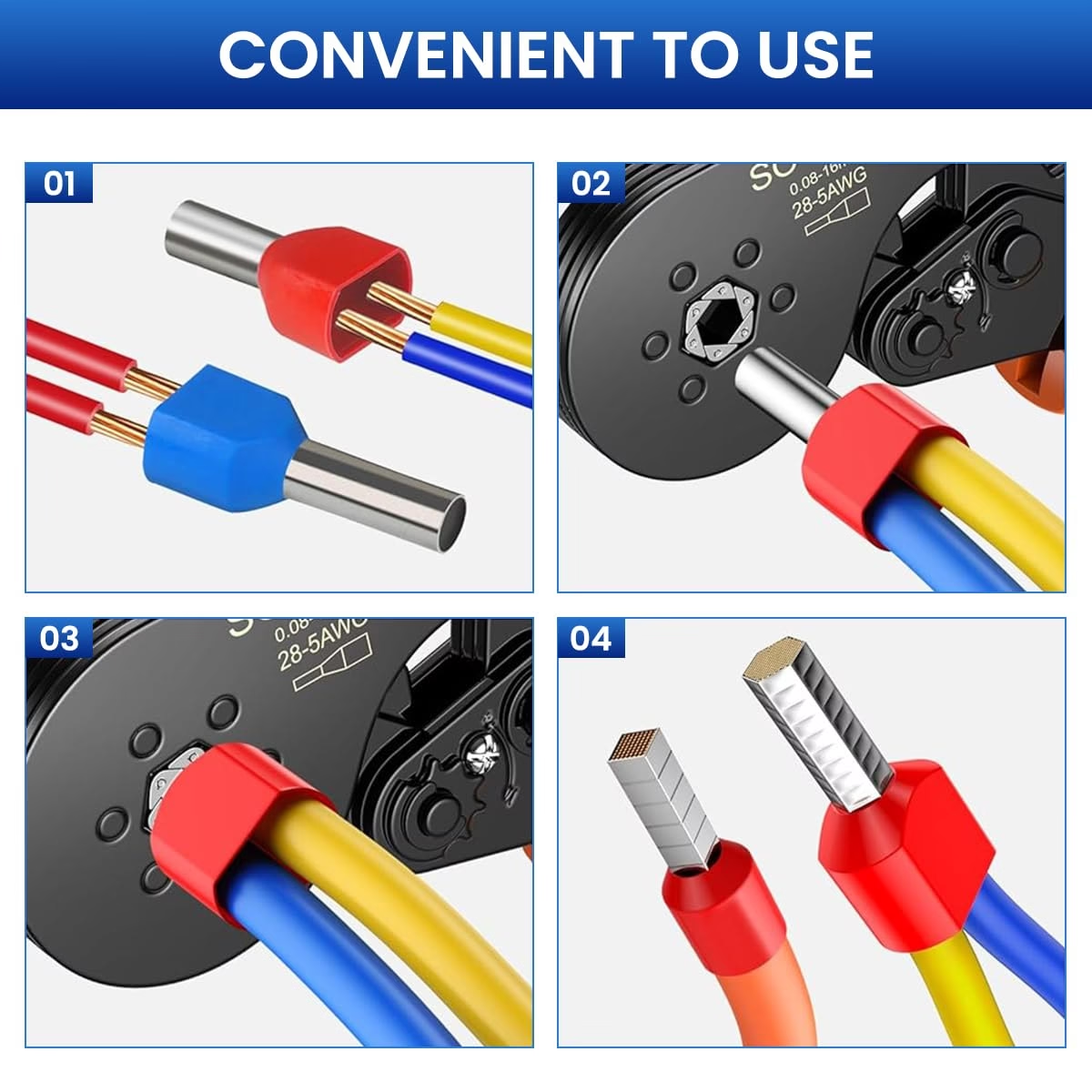

HOW ARE THEY USED?

A wire or cable is stripped to the same length as the terminal and pushed into the correct size ferrule through the collar so that the ends of the wire are flush with the end of the tube. A suitable size cable crimping tool is then used to crimp the metal tube to the wire.

| 0.5: Lead Section (mm) Orange | Lead Section (mm) Orange |

|---|---|

| 0.75: Lead Section (mm) Grey | Lead Section (mm) Grey |

| 1.00: Lead Section (mm) Yellow | Lead Section (mm) Yellow |

| 1.50: Lead Section (mm) Red | Lead Section (mm) Red |

| 2.50: Lead Section (mm) Blue | Lead Section (mm) Blue |

| 4.00: Lead Section (mm) Grey | Lead Section (mm) Grey |

| 6.00: Lead Section (mm) Yellow | Lead Section (mm) Yellow |

| 10.00: Lead Section (mm) Red | Lead Section (mm) Red |

| 16.00: Lead Section (mm) Blue | Lead Section (mm) Blue |

| 25.00: Lead Section (mm) Yellow | Lead Section (mm) Yellow |

| 35.00: Lead Section (mm) Beige | Lead Section (mm) Beige |

| 50.00: Lead Section (mm) Olive | Lead Section (mm) Olive |

| 70.00: Lead Section (mm) Yellow | Lead Section (mm) Yellow |