An explosion-proof mobile phone is a specialized device built for use in hazardous areas where flammable gases, dust, or vapors are present. Unlike regular phones, it’s engineered with intrinsic safety technology to prevent sparks or heat, complying with strict international standards like ATEX and IECEx.

- 24x7 Support +968 99 26 36 46

- Premium Quality

- 10 days Return & Exchange

- Deliver in 5-7 Days

- Worldwide Shipping

- Sellers can Quote

Explosion-Proof Mobile

An explosion-proof mobile phone is a highly specialized communication device meticulously engineered to operate safely in hazardous industrial environments. These are locations where flammable gases, vapors, combustible dust, or ignitable fibers are present, posing a significant risk of ignition or explosion. Unlike standard consumer smartphones, these devices are designed with intrinsic safety technologies and robust construction to eliminate any potential ignition sources, such as sparks, excessive heat, or electrostatic discharge. This critical safety aspect is validated through rigorous testing and certification compliance with international standards like ATEX (European Union), IECEx (global), and UL (United States). These certifications precisely define the “zones” or “divisions” where the device can be safely deployed, indicating its approved level of explosion protection.

Beyond their inherent safety features, explosion-proof mobiles are built for unparalleled durability. Their construction typically involves reinforced casings made from resilient, impact-resistant materials, often incorporating shatterproof displays like toughened glass. They boast high Ingress Protection (IP) ratings, commonly IP68, guaranteeing complete immunity to dust ingress and continuous water immersion. Furthermore, these devices are engineered to withstand extreme physical abuse, including drops, vibrations, and broad temperature fluctuations, frequently meeting stringent military-grade standards such as MIL-STD-810H.

Functionally, they provide essential communication capabilities, including robust 4G or 5G connectivity, Wi-Fi, and Bluetooth. Many models incorporate features tailored for demanding industrial use, such as extra-loud loudspeakers for noisy environments, programmable buttons for dedicated push-to-talk (PTT) communication, or emergency SOS functions. Displays are often optimized for visibility in various lighting conditions and for operation while wearing thick work gloves. Some advanced versions integrate specialized sensors for environmental monitoring or support intrinsically safe applications vital for lone worker safety, asset tracking, or digital data collection in hazardous zones. Their long-lasting, often field-replaceable batteries are crucial for extended operational periods in remote or challenging work sites, minimizing downtime and maximizing safety.

Related

Related products

Hydrogen Sulfide H2S Gas Detector | High Alarm

Schneider TransferPacT Automatic Transfer Switch

Digital Hardness Tester

Megger MIT310 Insulation Tester Megohmmeter

Siemens 3RT2025-1BB40 Contactor 24VDC – 7.5kW, 400V

Fluke 9040 Phase Rotation Indicator LCD

Rotary Changeover Switch SZW | 660V 40A 3-Position 3-Pole,

ر.ع.28.500Original price was: ر.ع.28.500.ر.ع.27.400Current price is: ر.ع.27.400.

Phoenix Contact VAL-MS 230 | Surge 275V AC 40kA

Portable Electric Space Heater –1500 / 750W

ر.ع.38.000Original price was: ر.ع.38.000.ر.ع.37.300Current price is: ر.ع.37.300.

German Schuko Socket | 2Gang 2P+E IP54

ر.ع.13.800Original price was: ر.ع.13.800.ر.ع.12.400Current price is: ر.ع.12.400.

Voltage Protection Relay | Over / Under Voltage Protector

Fluke 115 True RMS Digital Multimeter – AC/DC Volt

Terminal Block Connector | Din Rail Type

ر.ع.0.800 – ر.ع.2.500Price range: ر.ع.0.800 through ر.ع.2.500Select options This product has multiple variants. The options may be chosen on the product page

Multifunctional Portable Waterproof DB

ر.ع.40.000Original price was: ر.ع.40.000.ر.ع.38.800Current price is: ر.ع.38.800.

Schneider Acti9 iC60N MCB – A9F74332

High Power Adjustable Resistor | 50W-10KW 5Ω–1kΩ

Schneider Acti9 iSW 2P 63 A Isolator – A9S65263

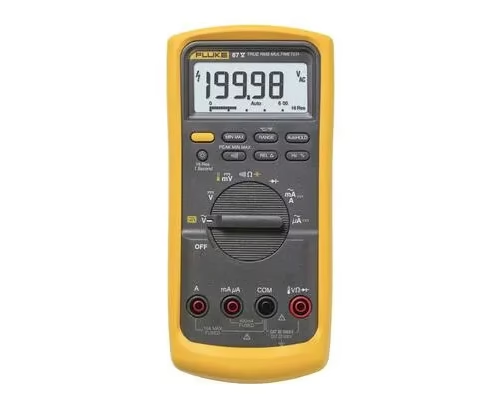

Fluke 87V TRMS Industrial Multimeter