Copper Adhesive High-Temperature Tape

Double-side Conductive Copper Foil Adhesive Tape Signal Enhancement High-temperature Tape Anti-interference Shielding Tape 10M

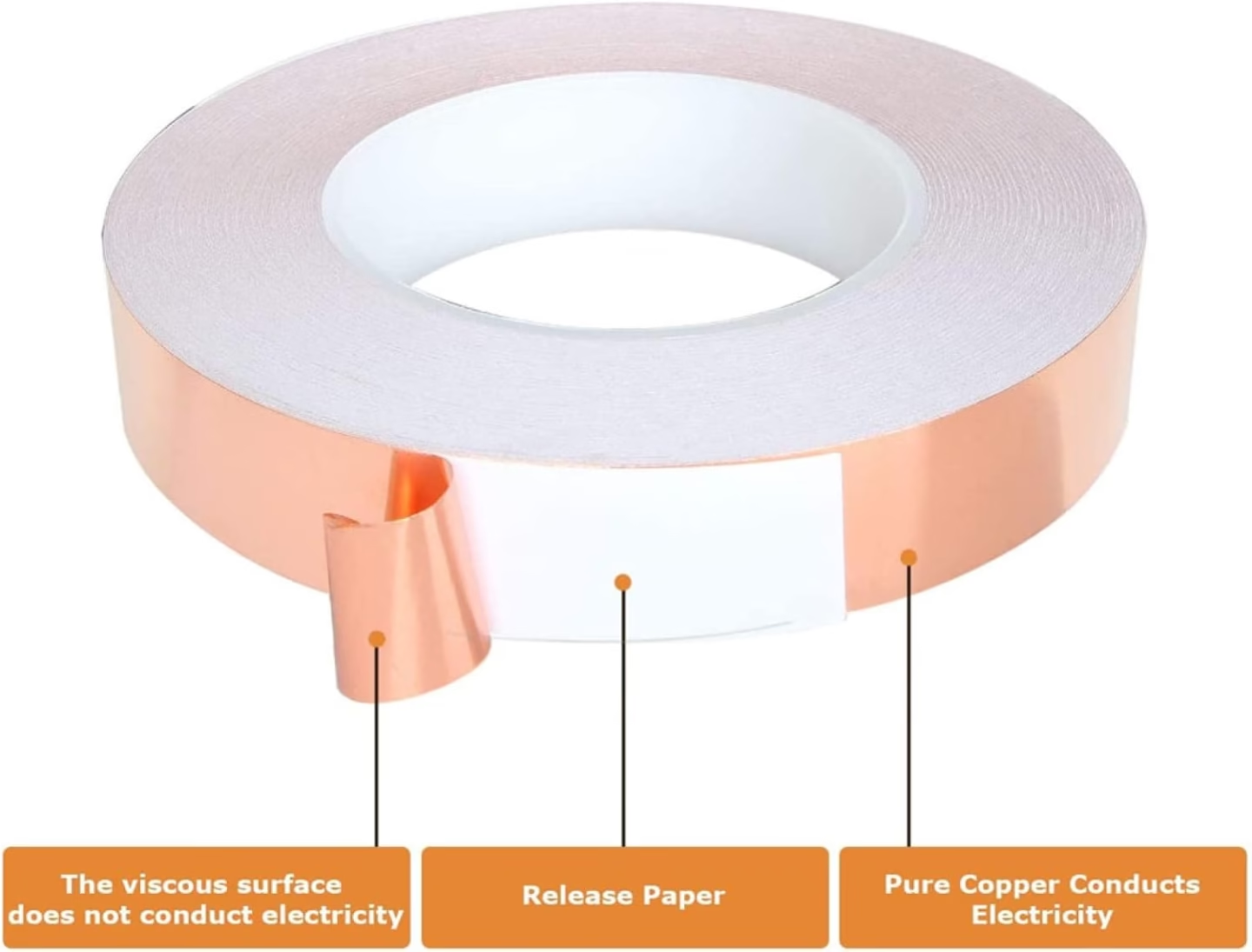

Copper Foil Backing: A thin, ductile layer of copper (often 0.03mm to 0.1mm thick). It can be plain copper or have a conductive adhesive, but not all copper tapes are electrically conductive.

High-Temperature Adhesive: A pressure-sensitive silicone adhesive specifically formulated to withstand extreme heat (often from 180°C / 356°F up to 260°C / 500°F or higher for short periods).

Release Liner: A protective backing (usually paper or PET) that is removed before application.

High Temperature Resistance: Its primary feature. It can endure soldering, wave soldering, reflow processes, and high-temperature masking without melting or leaving significant residue.

EMI/RFI Shielding: Copper is an excellent conductor. When the adhesive is also conductive, the tape can create a shielded enclosure to block or contain electromagnetic or radio frequency interference.

Thermal Conductivity: Copper efficiently spreads and dissipates heat, making it useful in some thermal management applications (e.g., as a heat spreader or to channel heat away).

Corrosion Resistance: The copper foil can be coated or treated (e.g., with a thin lacquer) to prevent oxidation and tarnishing.

Conformability & Ductility: Copper is malleable, allowing the tape to conform to irregular shapes, bends, and curves.

PCB (Printed Circuit Board) Manufacturing & Repair:

High-Temperature Masking: Protecting specific components or gold fingers during wave soldering or conformal coating.

Shielding: Creating ground planes or enclosures to shield sensitive circuits from EMI.

Repair: Fixing broken traces or creating jumper connections (requires conductive adhesive).

Electronics & Electrical Shielding:

Shielding cables, connectors, or enclosures for electronic devices.

Sealing seams and gaps in shielded rooms or cabinets.

Heat Management:

Acting as a temporary or permanent heat spreader on components.

Used in lithium-ion battery packs for thermal diffusion and current collection.

Plating & Anodizing Masking:

Protecting areas of parts from being plated, painted, or anodized during batch processing.

HVAC & Ductwork:

Sealing joints in high-temperature air ducts due to its flexibility and heat resistance.

CRITICAL DISTINCTION: Not all copper foil tapes are high-temperature tapes. Standard craft-grade copper tape uses an acrylic adhesive that will melt and fail under heat.

When selecting, you must specify:

Adhesive Type:

Silicone Adhesive: For true high-temperature performance (the most common type for this purpose).

Acrylic Adhesive: For general-purpose use at lower temperatures (usually up to ~120°C).

Electrically Conductive Adhesive (ECA): Contains conductive particles (e.g., silver or nickel) to ensure electrical continuity through the adhesive layer. Essential for EMI shielding.

Copper Thickness & Type: Measured in microns or mils. Thicker foil offers better shielding and durability.

Temperature Rating: Always check the manufacturer’s datasheet for continuous and peak temperature ratings.

Backing Treatment: Determine if you need anti-oxidation treatment for long-term use.

- 24x7 Support +968 99 26 36 46

- Premium Quality

- 10 days Return & Exchange

- Deliver in 5-7 Days

- Worldwide Shipping

- Sellers can Quote

Original price was: ر.ع.18.500.ر.ع.16.700Current price is: ر.ع.16.700.